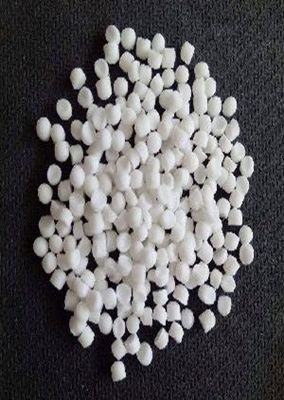

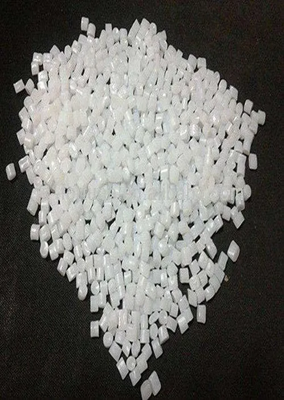

HDPE granules

HDPE (High-Density Polyethylene) granules are a versatile plastic material known for their high strength-to-density ratio. These granules are used in the production of a wide range of products, including bottles, piping, and plastic bags. HDPE granules are valued for their excellent chemical resistance, durability, and impact resistance, making them suitable for both industrial and consumer applications. They also have good thermal resistance, maintaining stability at various temperatures. The material is lightweight yet strong, and it is also recyclable, contributing to sustainable manufacturing practices.